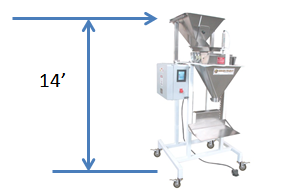

The supply hopper, located above the bagging scale, is about 14’ above the floor. A supply conveyor, sometimes called a feed conveyor, is used to get the processed product up and into the bagger’s supply hopper.

The supply hopper, located above the bagging scale, is about 14’ above the floor. A supply conveyor, sometimes called a feed conveyor, is used to get the processed product up and into the bagger’s supply hopper.

Feed conveyors can be used to move products from a variety of upstream process equipment (i.e. mixers, blenders, dryers) or bulk bags (FIBC). Most supply conveyors require a controlled infeed so that the product doesn’t overflow or backup.

There are 4 types of supply conveyors: auger (screw), bucket, belt, and pneumatic (vacuum). Which type of supply conveyor is used is dependent on the characteristics of the product, available floor space, and funding.

Belt Supply Conveyors

Belt conveyors can be used if the product is a pellet or chunks. Often cleats and/or side rails are added to contain the product. Since the belt is flat, belt conveyors usually require the most floor space. To reach a 14’ high supply hopper, a 45 degree incline conveyor is 20’ long and requires at least 14’ floor space. Video of a belt conveyor in action. More information on belt supply conveyors

Belt conveyors can be used if the product is a pellet or chunks. Often cleats and/or side rails are added to contain the product. Since the belt is flat, belt conveyors usually require the most floor space. To reach a 14’ high supply hopper, a 45 degree incline conveyor is 20’ long and requires at least 14’ floor space. Video of a belt conveyor in action. More information on belt supply conveyors

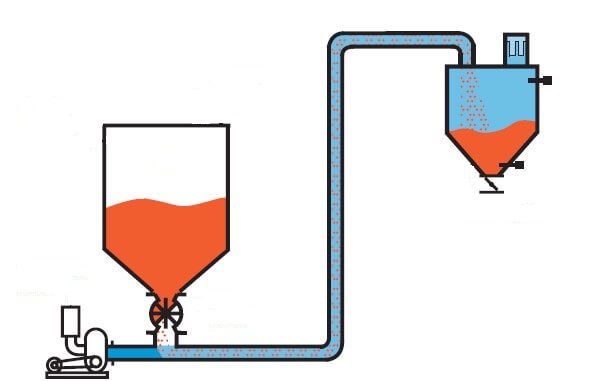

Pneumatic Supply Conveyors

Pneumatic conveyors can be used with dry powders, granules, and low density products that can be moved with air pressure or a vacuum through a tube. Pneumatic conveyors are very versatile. They can be piped relatively long distances, make turns, and have a small floor foot print. Video of a pneumatic conveyor in action. More information in pneumatic conveyors.

Pneumatic conveyors can be used with dry powders, granules, and low density products that can be moved with air pressure or a vacuum through a tube. Pneumatic conveyors are very versatile. They can be piped relatively long distances, make turns, and have a small floor foot print. Video of a pneumatic conveyor in action. More information in pneumatic conveyors.

Auger Supply Conveyors

Auger conveyors (also known as screw conveyors, spiral conveyors, helix conveyors, or worm conveyors) are typically straight like a belt conveyor. Semi-flexible screw conveyors with a flexible plastic tube and internal coil are also available. Auger conveyors are good for semi-fluid and non-abrasive applications like powders where crushing or grinding the product is not a concern. Video of a screw conveyor in action. More information on auger conveyors.

Auger conveyors (also known as screw conveyors, spiral conveyors, helix conveyors, or worm conveyors) are typically straight like a belt conveyor. Semi-flexible screw conveyors with a flexible plastic tube and internal coil are also available. Auger conveyors are good for semi-fluid and non-abrasive applications like powders where crushing or grinding the product is not a concern. Video of a screw conveyor in action. More information on auger conveyors.

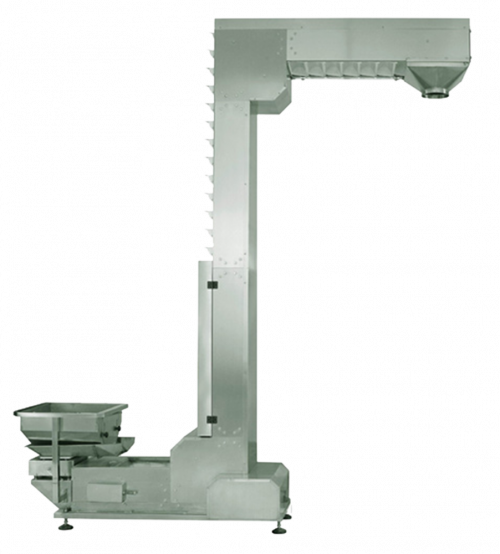

Bucket Supply Conveyors

Bucket conveyors can require the least amount of floor space since they can lift the product vertically. Bucket conveyors can deliver most products like feed, grain, or pellets. Fragile products can be safely handled. Video of a bucket conveyor in action. More information on bucket conveyors.

Bucket conveyors can require the least amount of floor space since they can lift the product vertically. Bucket conveyors can deliver most products like feed, grain, or pellets. Fragile products can be safely handled. Video of a bucket conveyor in action. More information on bucket conveyors.

Options available for supply conveyors include an infeed hopper located at the input end, stainless steel and food grade construction, a discharge spout/chute, and variable speed controls.