“Tube” type poly bags are fed into the Sharp MAX™ Continuous Roll Bagging System where the bag is opened, filled with product, heat sealed and separated.

The MAX™ 12 accepts bags up to 12” wide and 40” long and the MAX™ 20 accepts bags up to 20” wide and 40” long. They can be set up for either horizontal or vertical loading. Acceptable bag materials include: Polypropylene (PP), heavy duty PP, military specification, gamma patient, metalized barrier, electric static discharge (ESD), modified atmospheric packaging (MAP), non-scratch, anti-static and vapor corrosive inhibitor (VCI).

Typical markets include: food, fulfillment, hardware, hobby, injection molding, medical, parts and retail.

Bar codes, graphics and alphanumeric can be imprinted on the bags by either a stand-behind or integrated “first-bag-out” printer. The MAX™ Systems easily interface with all types of in-feed and out-feed devices.

Specifications:

- Up to 70 bags/min.

- Bag width 2”-20”

- Bag length 3.5”-32”

- Bag gauge 1 mil – 4 mil

- Bag roll size 10”, 12”, 14” or fan-folded

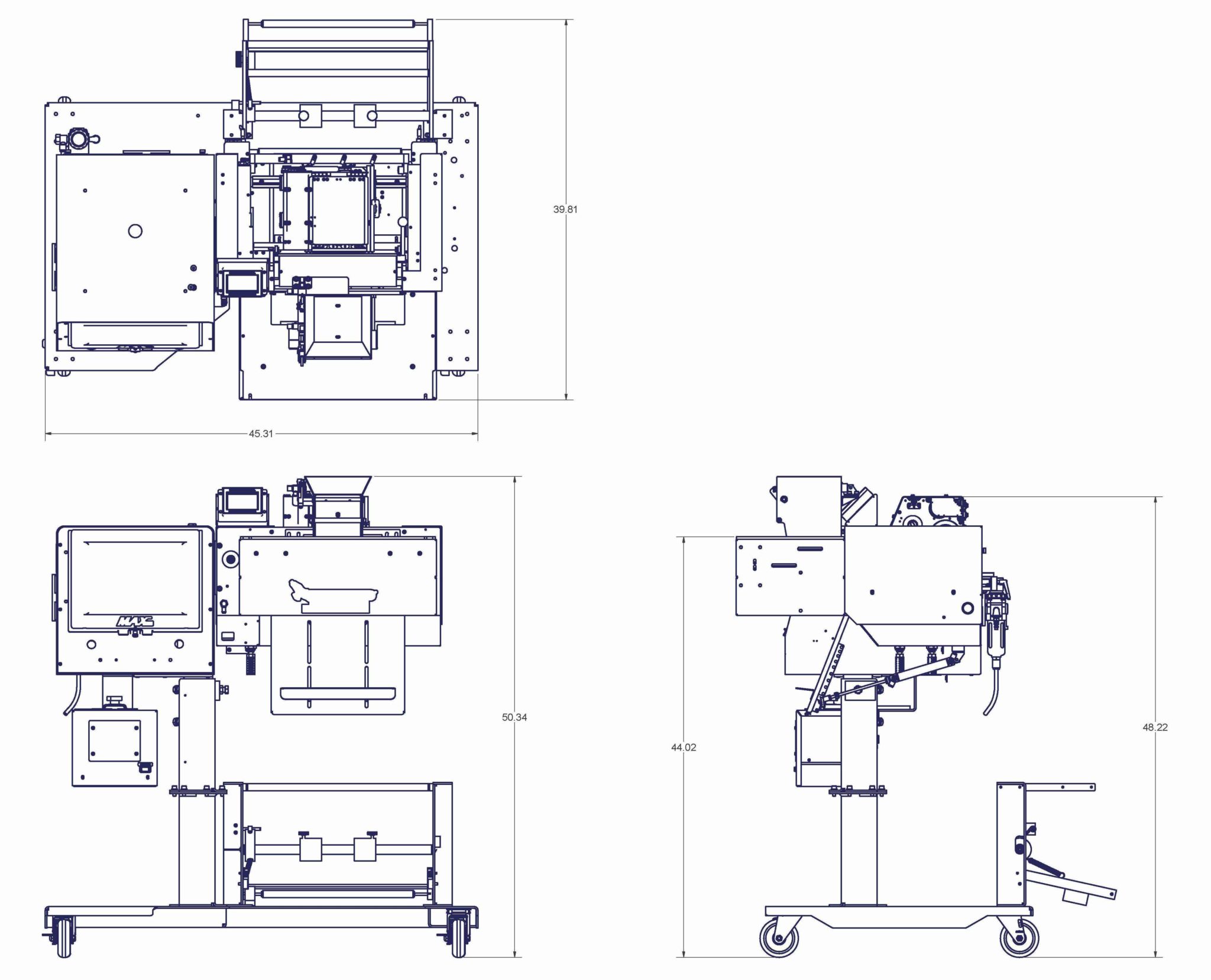

- 39.1”D x 46.5”W x 35”H (base unit)

Options:

- MAX-SB includes stand-behind printer

- MAX-I includes integrated “first-bag-out” printer

Utility Requirements:

- Electrical: 110 VAC 50 HZ, 15/4 AMPS

- Air: 80 PSI, 5 scfm, 5.5 bar

Dimensional Drawing