The Northwest Bagger ABH-1 is a single headed bagger for produce such as: onions, potatoes, apples, avocados, baby carrots, charcoal, nuts & bolts, oranges, peanuts & walnuts.

The conveyor feeds directly into the bagger scoop and automatically stops when the desired weight is reached. The ABH-1 can fill 3 to 50 lb. bags at a rate of 350 to 450 bags per hour. Options include a bag counter and box holder

STANDARD FEATURES:

- scoop head

- magnetic clutch assembly

- electronic load cell assembly

- conical hopper

- cleated belt conveyor

- variable speed drive

- casters

OPTIONS:

- Bag counter

- Box holder

UTILITIES:

- Air: NA

- Electrical: 110 VAC, 1 Ph, 60 Hz

STARTUP SERVICES

Inpak Systems offers a startup service on your new Model ABH-1. This includes verifying the Model ABH-1 is operating properly to factory specifications. The startup service includes operation verification, operator training and maintenance training.

PREVENTIVE MAINTENANCE SERVICES

To prevent downtime and costly emergency repairs, preventive maintenance (PM) services are available for your Model ABH-1. To ensure your Model ABH-1 operates at maximum efficiency, PMs can be arranged to fit your production schedule.

IN-PLANT REPAIR SERVICES

Inpak Systems offers in-plant repair of your Model ABH-1. Our experienced, factory-trained, and certified technicians use genuine OEM parts to ensure your Model ABH-1 is restored to original factory operating specifications. Dispatched from either our WI or OH locations ensure a quick response throughout the Midwest.

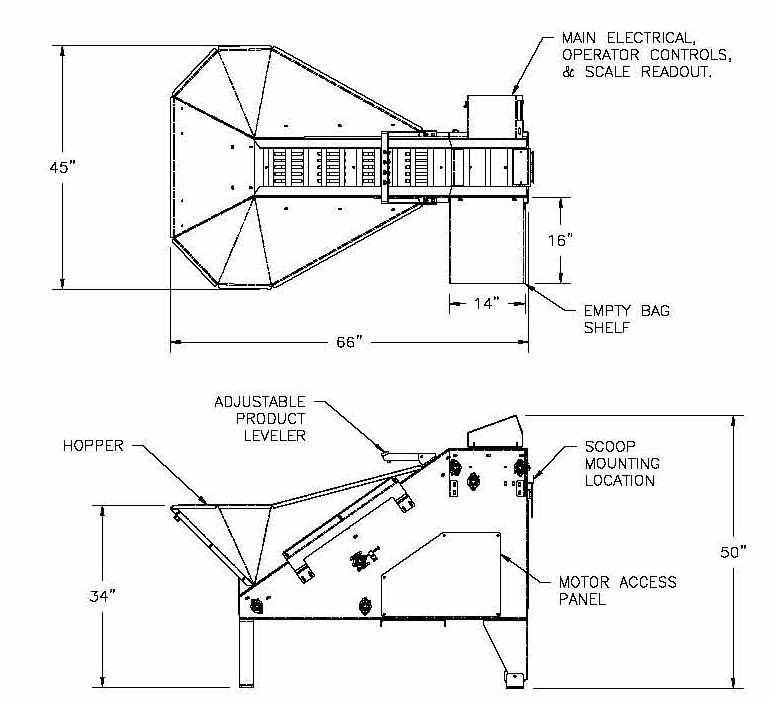

APPROXIMATE DIMENSIONAL DRAWING