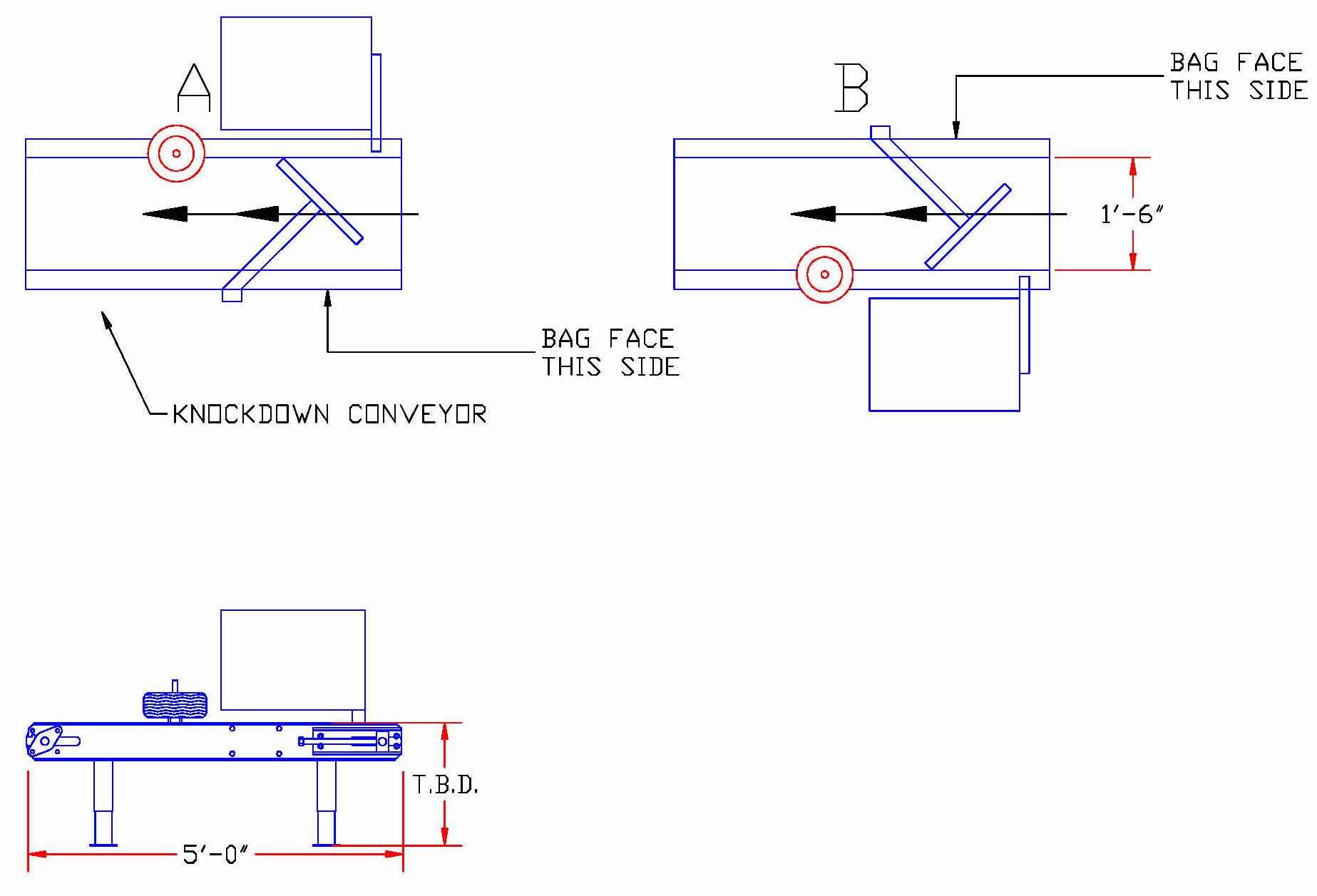

The JEM International KD5 is a knockdown, bag turning, conveyor that receives vertical standing bags, knocks them down, and turns them 90 degrees. The knockdown arm pushes the top of the bag over while the knockdown plate pushes the bottom of the bag out. The roller assembly catches the upper half of the bag and holds it while the lower half of the bag is spun around. The bags exit the conveyor flat and bottom first onto a separate conveyor.

This conveyor is used for feeding flattening conveyors, miscellaneous printing systems or whenever the position of the bag is critical prior to palletizing.

STANDARD FEATURES:

- 5’ x 24” smooth top belt

- 60 FPM (std.)

- adjustable knockdown arm

- adjustable knockdown plate

- adjustable turning wheel assembly

- adjustable height legs

- 1 HP drive motor

- mild steel construction

OPTIONS:

- NA

UTILITIES:

- Air: NA

- Electrical: 110VAC, 1PH or 230/480 VAC, 3Ph

STARTUP SERVICES

Inpak Systems offers a startup service on your new KD5 Bag Turner. This includes verifying the KD5 Bag Turner is operating properly to factory specifications. The startup service includes operation verification, operator training and maintenance training.

PREVENTIVE MANTENANCE SERVICES

To prevent downtime and costly emergency repairs, preventive maintenance (PM) services are available for your KD5 Bag Turner. To ensure your KD5 Bag Turner operates at maximum efficiency, PMs can be arranged to fit your production schedule.

IN-PLANT REPAIR SERVICES

Inpak Systems offers in-plant repair of your KD5 Bag Turner. Our experienced, factory-trained, and certified technicians use genuine OEM parts to ensure your KD5 Bag Turner is restored to original factory operating specifications. Dispatched from either our WI or OH locations ensure a quick response throughout the Midwest.

APPROXIMATE DIMENSIONAL DRAWING