The JEM International BF-10 is a 10’ long, incline, dual belt, bag flattening conveyor. The BF-10 is designed to flatten bags to be palletized. Bags that have been flattened tend to make pallets squarer, hold together better, and have less freight damage than pallets with un‐flattened bags.

The BF-10 has a 10’ x 24” flat belt bottom conveyor with an opposing 5½ x 24” flat belt upper conveyor. It has dual, fixed speed, drive motors with 12” inlet height & 42” inch discharge height. The upper conveyor has flexible spring loaded suspension that maintains pressure on the bag as it passes between.

STANDARD FEATURES:

- 10’ bottom belt

- 5.5’ upper belt

- 24” wide flat belts

- 12” inlet & 42”outlet heights (std.)

- 110 FPM

- 1.5 & 1 HP motors

OPTIONS:

- cleated belt

- 1 Ph motors

UTILITIES:

- Air: NA

- Electrical: 220VAC, 3Ph, 60 Hz

STARTUP SERVICES

Inpak Systems offers a startup service on your new BF-10 Bag Flattener. This includes verifying the BF-10 Bag Flattener is operating properly to factory specifications. The startup service includes operation verification, operator training and maintenance training.

PREVENTIVE MANTENANCE SERVICES

To prevent downtime and costly emergency repairs, preventive maintenance (PM) services are available for your BF-10 Bag Flattener. To ensure your BF-10 Bag Flattener operates at maximum efficiency, PMs can be arranged to fit your production schedule.

IN-PLANT REPAIR SERVICES

Inpak Systems offers in-plant repair of your BF-10 Bag Flattener. Our experienced, factory-trained, and certified technicians use genuine OEM parts to ensure your BF-10 Bag Flattener is restored to original factory operating specifications. Dispatched from either our WI or OH locations ensure a quick response throughout the Midwest.

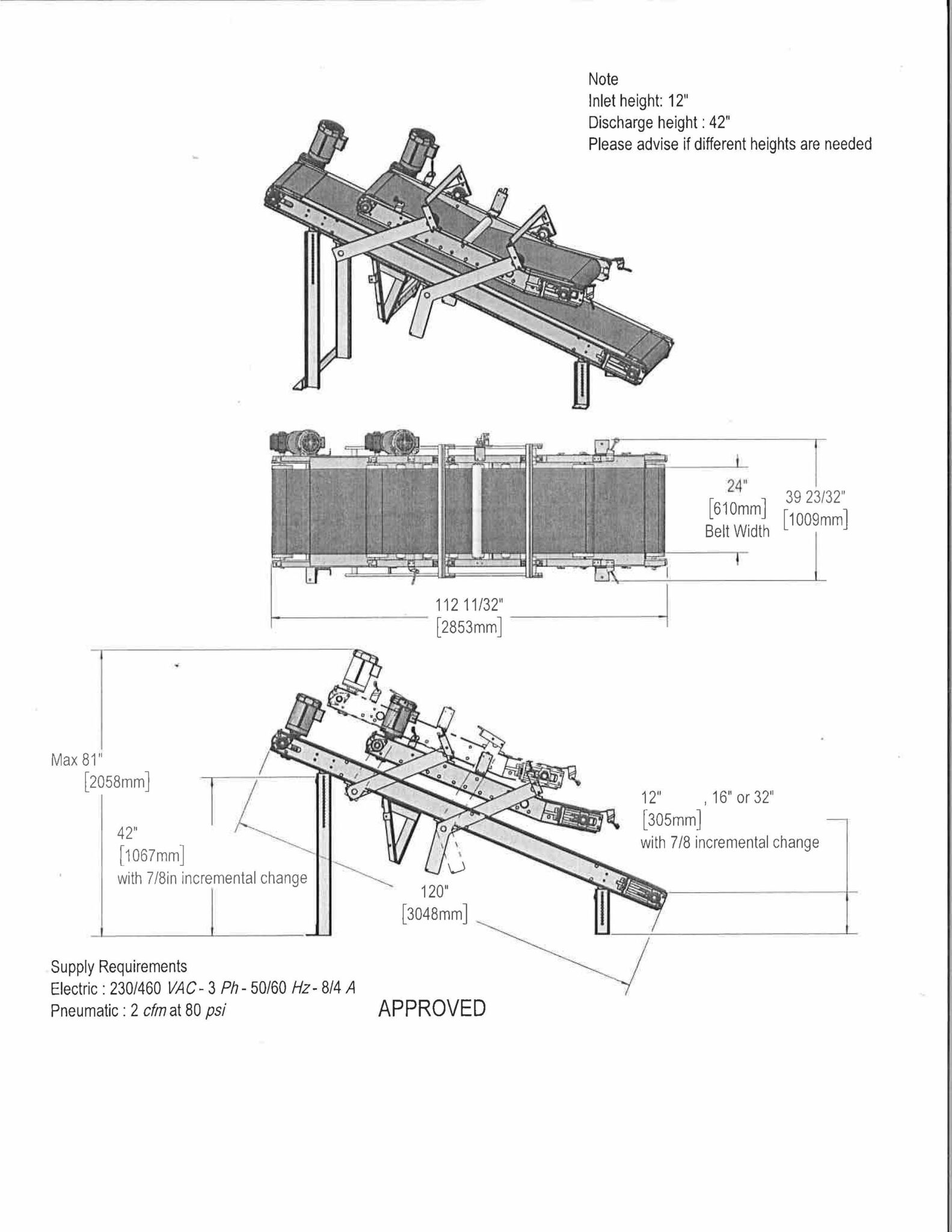

APPROXIMATE DIMENSIONAL DRAWING