The Choice Bag Equipment (CBE) Model 500 is a semi-automated, gravity, gross weigh, bulk bag filler for packaging 1,000 lb. to 4,400 lb. (454KG – 2,000KG) IBCs, bulk bags, super sacks & Gaylord boxes at a rate of up to 25 bags/hour.

The 500 Series is an automatic gross weighing filler that simultaneously fills and weighs product directly into the bag. The 500 Series is idea for free flowing powders, granular & pelleted materials such as fertilizer, corn, soybeans, salt, sugar, sand, limestone, refractory materials and plastic pellets. This filler is capable of weighing non-free-flowing materials with specialized product feeding devices.

The 500 Series IBC filler has a totally enclosed product flow path from the supply hopper bin all the way into the bag. It can also be equipped with an optional air operated dust tight bag fill spout making the 500 Series the cleanest filling IBC filler available in the industry.

Operation:

The 500 Series gravity style IBC filler has a specially designed product flow gate powered by gravity. Product flows by gravity from the supply hopper bin into the product feed inlet at the top of the machine. When a fill cycle is initiated, the product flows through the slide gate into a spout and into the bag.

Standard Features

- Weight Range: 1,000 lb. to 4,400 lb. (500KG to 2,000KG)

- Fill Rate: up to 25 bags/hour

- Typical Scale Weight Accuracy” +/-0.5% of Target Weight

- Bag size: 48”x48”x66”

- Totally enclosed product flow path

Options:

- Dust Collector (600 CFM minimum)

- Vibratory Bag Densifier (220/440 VAC, 3 ph, 60 Hz)

Utility Requirements:

- Air: 80 PSI @ 1 CFM per bag fill cycle (base model does not require air)

- Electrical: 110 VAC, 1 ph, 60 Hz

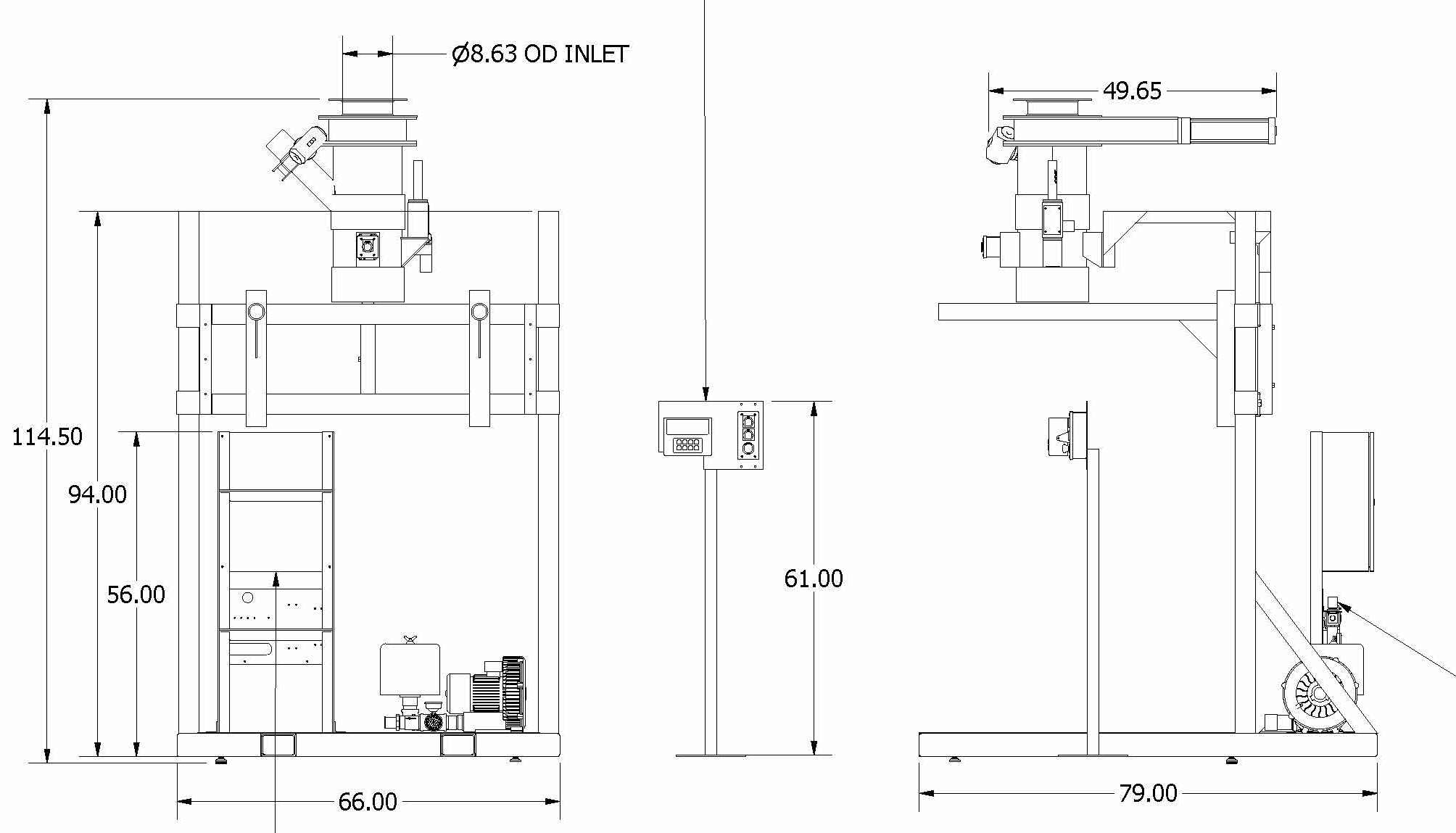

Approximate Dimensional Drawing: