Model 4000 is a bulk bag unloader. It is used for discharge product from bulk bags which are sometimes called: big bags, jumbo bags, totes, FIBC, super sacks, or jumbo sacks.

The fork lift model uses a forklift to place the bulk bag on 4 swivel latch hooks of the bag cradle on top of the discharge hopper.

The trolley hoist model uses an electric trolley hoist to raise/lower the bag cradle and travel forward/reverse to place the bag over the discharge hopper.

The Model 4000 has a heavy wall structural tube frame is designed for 2,000 to 4,000 bulk bags and includes: a 54” square bag support pan, a dust shroud with a dust pick-up stub, dust tight bag tie-off area, and product spout with discharge flange.

STANDARD FEATURES

- Heavy wall structural tube frame

- Forklift style bag lift

- Bag cradle with swivel latch hooks

- 2,000 lb. capacity

- 54” square bag support pan/discharge spout

- Dust shroud with 4” diameter dust pick-up stub

- Dust tight bag tie-off box with easy access door

- Products spout with discharge flange

OPTIONS:

- 4,000 lb. capacity

- 304 stainless steel product contact surfaces

- Electric trolley hoist assembly with NEMA 12 controls

- Vibrator and isolators to facilitate product discharge

- Pneumatic bag manipulators with controls

- Pneumatic pinch gate bag closer with controls

- Bag slitter for one time use bags

- Bag liner spring tensioner

- Bag liner pneumatic tensioner

- Fork lift pockets

- Door switch to indicate open or closed

- Knife gate

- Anti-corrosive construction

- Food grade construction

- Special paint finishes

UTILITY REQUIREMENTS:

- Air: NA

- Electrical: NA

STARTUP SERVICES

Inpak Systems offers a startup service on your new 4000 Bulk Bag Unloader. This includes verifying the 4000 Bulk Bag Unloader is operating properly to factory specifications. The startup service includes operation verification, operator training and maintenance training.

PREVENTIVE MAINTENANCE SERVICES

To prevent downtime and costly emergency repairs, preventive maintenance (PM) services are available for your 4000 Bulk Bag Unloader. To ensure your 4000 Bulk Bag Unloader operates at maximum efficiency, PMs can be arranged to fit your production schedule.

IN-PLANT REPAIR SERVICES

Inpak Systems offers in-plant repair of your 4000 Bulk Bag Unloader. Our experienced, factory-trained, and certified technicians use genuine OEM parts to ensure your 4000 Bulk Bag Unloader is restored to original factory operating specifications. Dispatched from either our WI or OH locations ensure a quick response throughout the Midwest.

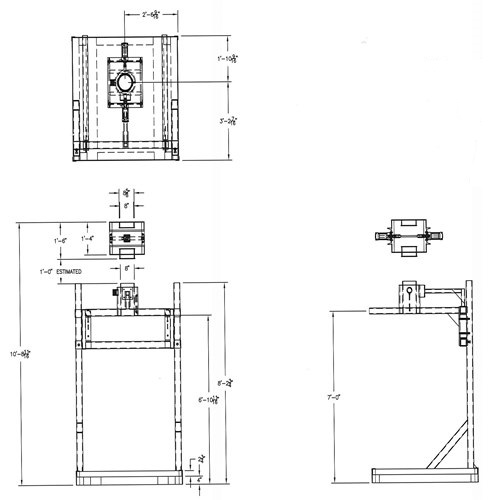

APPROXIMATE DIMESIONAL DRAWING