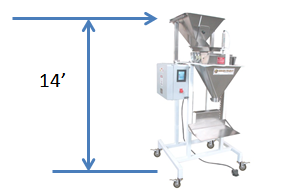

The supply hopper is located above the bagging scale is about 14’ above the floor. Often a supply conveyor, sometimes called feed conveyor, is needed to get the processed product up and into the supply hopper.

The supply hopper is located above the bagging scale is about 14’ above the floor. Often a supply conveyor, sometimes called feed conveyor, is needed to get the processed product up and into the supply hopper.

Feed conveyors can be supplied from a variety of upstream process equipment (i.e. mixers, blenders, dryers) or bulk bags (FIBC). Most supply conveyors require a consistent, controlled infeed so that the product doesn’t overflow or back up.

There are 4 types of industrial supply conveyor systems: auger (screw), bucket, cleated belt, and pneumatic. Which type of supply or feed conveyor is used is dependent on the characteristics of the product, available floor space, and funding.

Contact us to receive more information about our feed conveyor product line or fill out our Packaging Solutions Worksheet to inform us of your specific needs. Our packaging systems experts will then find the right supply conveyor for you.